By their very design fin fan radiator sets are liable to atmospheric fouling and should a power station be positioned near to agricultural land or other heavy industrial plants then fouling can quickly become blockages within the fin fan units. Ensuring that your fin fans are running efficiently means that the rest of your plant system can perform effectively.

Chemcleanzio uses excellent methods and is a resourceful contractor. Chemcleanzio appreciates the value of time and will work with you to ensure that fin fan downtime is minimised and production throughput is improved. High pressure jetting can distort the aluminium fins. Our technicians use an environmentally friendly chemical foam that saturates and expands into every crevice of the heat exchanger. A low pressure rinse minimizes overspray and is safer for both personnel and the equipment. The traditional cleaning method (hydroblasting) damages delicate fin fans and compacts the debris into the center of the tube stack. Our chemical process completely removes dirt, debris and corrosive elements without damaging equipment.

Fouled Air Cooled Fin Fan Heat Exchangers could mean increased energy costs. A dirty or fouled fin fan system can lead to a dramatic reduction in your plants efficiency and output. During the hot summer months a fouled system could require plant rates to be reduced, costing your facility lost revenue while exposing equipment to extreme conditions and potentially reducing the units overall life.

Foam Cleaning Technology

Our technicians use an environmentally friendly chemical foam that saturates and expands into every crevice of the heat exchanger. A low pressure rinse minimizes overspray and is safer for both personnel and the equipment. The traditional cleaning method (hydroblasting) damages delicate fin fans and compacts the debris into the center of the tube stack. Our chemical process completely removes dirt, debris and corrosive elements without damaging equipment.

Online or Offline Cleaning

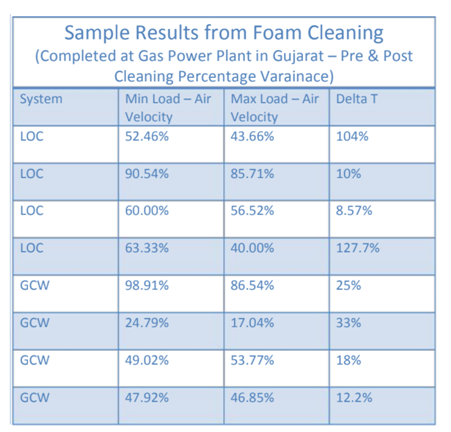

Fin Fan Cleaning can be done either Offline during a shutdown or Online during an operational plant by alternating the fans to ensure no downtime. Our Foam Cleaning technology can give you upto 40% increase in air flow. Sample results for one of the refineries recently serviced by us led to over 60% increase in air flow

Contact Us today for your Finfan Cleaning Requirements